Our testing laboratory no. 1511 fulfills the ČSN EN ISO/IEC 17025:2018 standard, is accredited and profesionally supervised by the Czech Accreditation Institute.

More information about the laboratory accreditation .

We offer

Custom measurements with a modern measuring technique are provided by qualified workers, who are ready to offer you:

- An accurate measuring of geometrical values (proportions, deviations from the shape and positions) and surface structure (roughness measuring)

- CNC 3D measuring, measuring of general shaped surfaces based on the CAD data.

- Elaboration of data reports and analyses of the competence of measuring machines

- The adjustment of SW Calypso communication with SW for the evaluation of the machines´ competence, processes and qs-STAT measuring systems

- The creation of measuring programmes for the CNC SW Calypso coordinate measuring machines

- Supporting systematics of measurement

- Preparation of inspection reports for the customer´s documentation (VDA EMPB, QS-9000 ISIR, CFG-1001 GM/Ford/D.C.)

We specialise primarily in car industry and plastic components, but we are able to ensure product measuring, form measuring, or measuring of the prototypes from other industries as well. Furthermore, our regular customers include companies from the area of precise engineering, aerospace industry, arms industry, printing industry, home electronics or medical technology.

The price of custom measurings is individual, and we will be happy to inform you after receiving your particular request.

If you are interested in our service, do not hesitate to contact us on the telephone or by e-mail. You may also use our contact form.

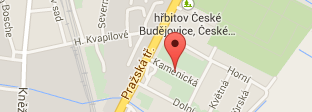

Place of Business

We run our accredited measuring laboratory in České Budějovice, at a place with a great transport accessibilty, very close to the main road to Prague. How can you reach us?

Technical Equipment

- Zeiss PRISMO 7 Vario - VAST XT coordinate measuring machine (3D measuring)

- Zeiss DuraMax – VAST XXT coordinate measuring machine (3D measuring)

- Zeiss O- Inspect 322 multisensor coordinate measuring machine (3D measuring)

- Calypso, Holos - Measuring SW, models processing in the format STEP etc.

- Mahr MarSurf XR 20 – GD 25 roughness tester

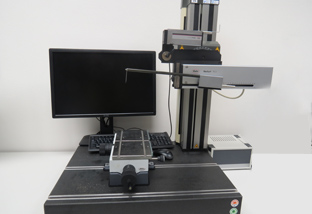

- Mahr MarSurf XCR 20 - PCV 200 formtester & GD 25 roughness tester

- Mahr MarForm MMQ 400 formtester (roundness tester)

- Mahr MarSurf LD 120 - LD 120 (form- & roughness tester)

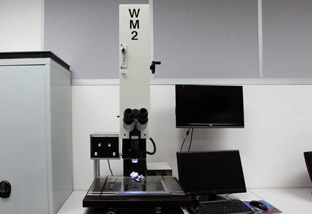

- Dr. Schneider WM2 microscope

- Links to Carl Zeiss standards

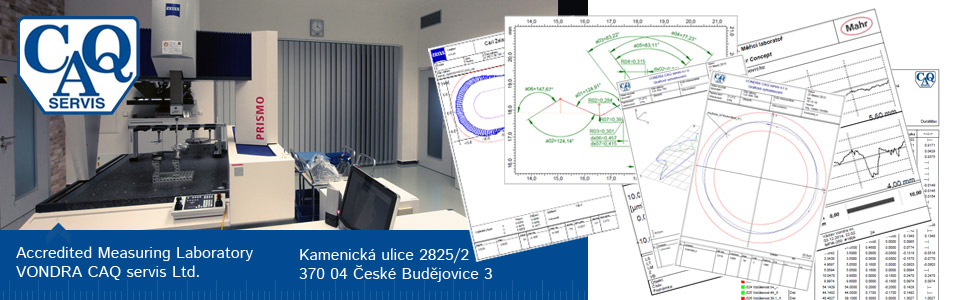

3D Zeiss PRISMO 7 Vario

- Measuirng range (x, y, z): 900, 1180, 700 mm

- VAST XT measuring head with an active scanning (3D measuring)

- measuring uncertainty U=(2,0 + L/250) µm

- Measured part weight up to 1300 kg

- Travel speed up to 300mm per second

3D Zeiss DuraMax

- Measuring range (x, y, z): 500, 500, 500 mm

- VAST XXT measuring head with a passive scanning (3D measuring)

- measuring uncertainty U=(2,4 + L/250) µm

- Measured part weight up to 100 kg

- Travel speed up to 300mm per second

3D Zeiss O-Inspect

- Measuring range (x, y, z): 300, 200, 200 mm

- VAST XXT measuring head with a passive scanning (3D measuring)

- Telecentric lense

- measuring uncertainty U=(2,4 + L/150) µm

- Measured part weight up to 20kg

- Travel speed up to 300mm per second

Mahr MarSurf XR20 - roughness

- drive unit GD25

- MFW 250 sensor

- measuring uncertainty for parameter Ra U=4,2%

- measuring uncertainty for parameter Rz U=3,4 %

Dr. Schneider WM2 microscope

- Measuring range (x,y): 250, 125 mm

- measuring uncertainty U=(3 + L/1250) µm

- Measured part weight: 20kg

Formtester Mahr MarForm MMQ 400-2

- For the measuring of shape and position deviations

- Measuring range (x, z): 280, 500 mm

- measuring uncertainty U(in the plane)=0,04 µm

Mahr MarSurf LD120 - contour & roughness

- measurement of contours and surface roughness by one scan of the profile section

- drive unit LD120

- Measuring range (x, z): 120, 750 mm

- measuring uncertainty U=2,25 µm

- measuring uncertainty for parameter Rz U=3%

Mahr MarSurf XCR 20 – contour & roughness

- measuring of contours and roughness at one measuring workplace

- drive unit PCV 200, measuring range (x;z) 200, 50 mm

- drive unit GD25

- measuring uncertainty U=(11,4 + L/5000) μm

- measuring uncertainty for parameter Ra U=4,2%

- measuring uncertainty for parameter Rz U=3,4 %

VONDRA CAQ servis Ltd.

VONDRA CAQ servis Ltd.  Accredited testing laboratory

Accredited testing laboratory